Avoiding Fines

How mistracking can affect your productivity and your bottom line and how Flexco tracking solutions can help

There is nothing more frustrating than watching your operation go from working at peak productivity to a complete stop because of an issue with your belt conveyor. Now imagine if your local regulatory agency drops by and starts issuing fines for those issues.

Flexco understands that you don’t have the time or money for downtime and fines. That’s why they conduct assessments on your entire conveyor system at no charge. During those assessments, one of the most common problems they come across is mistracking since even the slightest movement or change in the conveyor can throw the belt off track.

Mistracking can result in several productivity-stalling problems, including downtime and cost from total belt replacement; lost materials due to spillage from the mistracked belt; and safety hazards that could result in fines and the possibility of workplace injuries.

In the U.S., belt misalignment is the 11th highest violation given out by the Mine Safety and Health Administration. In underground coal specifically, it accounted for 2.5% (943) of total violations in 2018.

If caught early and fixed, a mistracking belt does little damage to the conveyor or the belt. However, if missed or left unfixed, other types of damage can occur.

Ideally, the way to fix a belt that is mistracking is to go straight to the source and eliminate the problem. And while some fixes are easy and will train your belt to function properly, some are cost prohibitive (moving or remodeling the structure), and some are beyond your control (weather conditions). When permanent structural changes cannot be made, devices must be used to help track the belt correctly.

Flexco has product solutions for mistracking belts:

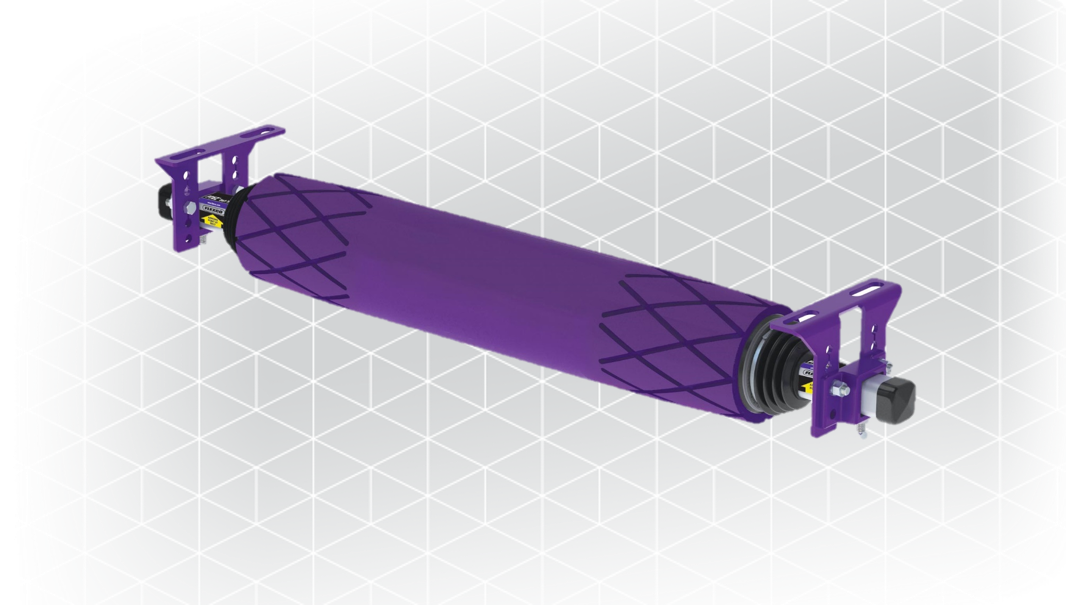

PTEZ™ Belt Trainer

The Flexco PTEZ™ Belt Trainer uses our patented “PTEZ mechanism,” responding and compensating immediately to belt misalignment using the tapered end roller profile to engage the training action. This ensures that the belt stays away from the structure and the material stays on the belt without the use of sensor or edge rollers. As a result, the PTEZ may be used in nearly any application to provide tracking and prevent damage to the belt or structure.

• Works for belts mistracking to one side or both sides

• Available in standard- and heavy-duty models

• Works with mechanically fastened and vulcanized belts, in wet or dry conditions

• Simple, adjustable mounting brackets ensure quick and accurate installation

• Can be installed on single direction or reversing belts

• Maximum Belt Tension:

o Standard-Duty: 1600 PIW (280 N/mm)

o Heavy-Duty: 2400 PIW (420 N/mm)

• Belt speeds up to:

o Standard-Duty: 1000 fpm (5 m/sec)

o Heavy-Duty: 1400 fpm (7 m/sec)

o Belt widths from 18" to 96" (450 to 2400 mm)

• Belt widths from 18" to 96" (450 to 2400 mm)

Search Available Product Options

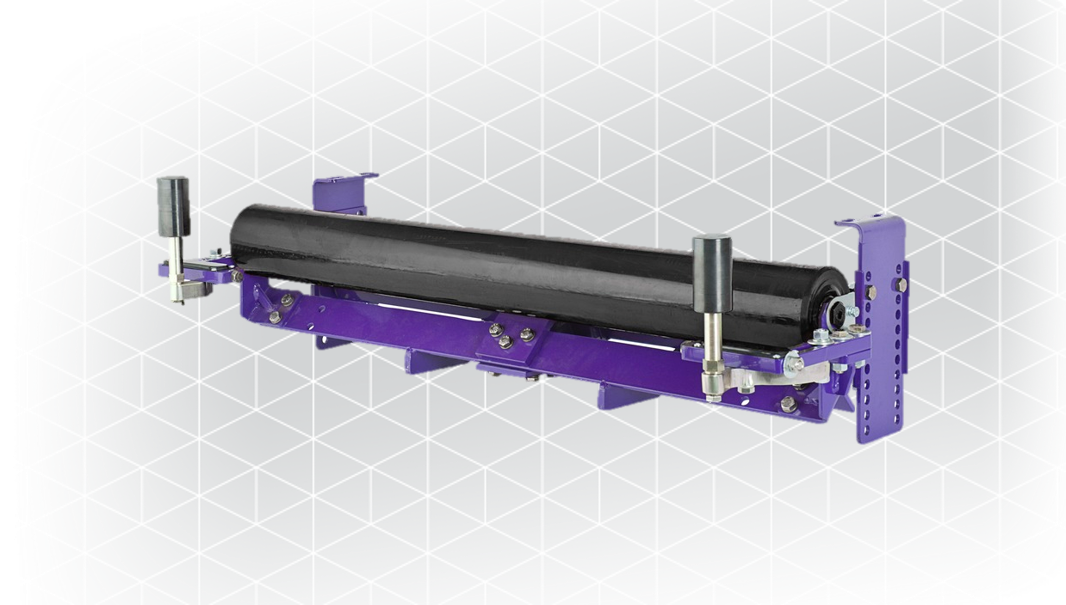

PT Smart™ Belt Trainer

The patented PT Smart™ Belt Trainer from Flexco uses sensor rollers to detect belt wander and our unique "pivot and tilt" design to instantly react to and compensate for belt misalignment, ensuring that the belt stays away from the structure and the material stays on the belt.

• Works for belts mistracking to one side or both sides

• Available in above-ground and underground models

• Works with mechanically fastened and vulcanized belts

• Features simple, adjustable mounting brackets that ensure quick and accurate installation

• Used on single-direction belts

• Return-side installation

• Maximum Belt Tension: 1600 PIW (280 N/mm)

• Belt speeds up to 1000 fpm (5 m/sec)

• Belt widths from 18" to 72" (450 to 1800 mm)

Search Available Product Options

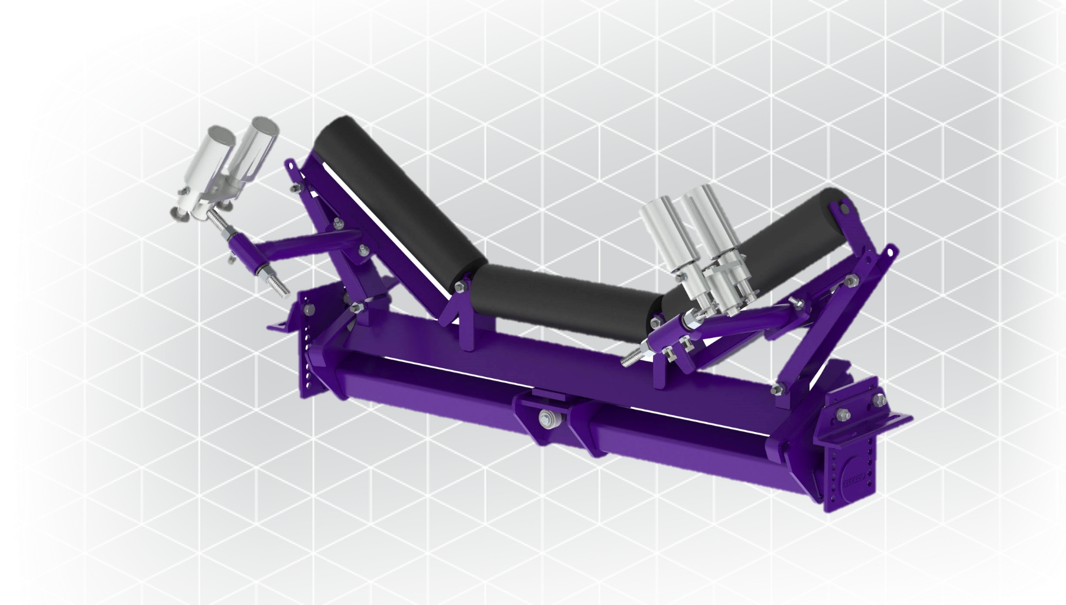

PT Max™ Belt Trainer

The Flexco PT Max™ Belt Trainer is the only true high-performance belt trainer on the market, proven in heavy-tonnage applications that test the strength and durability of your conveyor system. Thanks to our unique “pivot and tilt” design, the unit reacts and compensates instantly to belt misalignment, ensuring that the belt stays away from the structure and the material stays on the belt.

• Works for belts mistracking to one side or both sides

• Available in standard, heavy-duty, and super-duty models, and in top-, return-, and V-return models

• Works with mechanically fastened and vulcanized belts

• Dual rollers safeguard belt edges, reducing severe edge pressure and minimizing damage

• Easy to install and maintain – rollers can be replaced with standard on-site idler rollers

• Maximum Belt Tension:

o Standard Duty: 3000 PIW (525 N/mm)

o Heavy Duty: 6000 PIW (1050 N/mm)

o Super Duty:10000 PIW (1750 N/mm)

• Belt speeds up to 1200 fpm (6 m/sec)

• Belt widths from 24" to 84" (600 to 2100 mm)

Search Available Product Options

Find a Service Center

Find a Service Center