Fast, Easy Solutions for Conveyors in the Food Industry

Featuring endless belt splicing innovations with Novitool® and belt cleaning opportunities with the FGP Food Grade Precleaner

Every second your belt conveyor system isn’t running counts. Lost production time, unnecessary product waste, lost labor hours, and missed delivery schedules can really affect your bottom line.

Downtime, sanitation and cross contamination, and product waste are three of the biggest pain points when it comes to conveyors in the food industry. Flexco understands your challenges and offers several solutions that will help you maximize your productivity and address your sanitary needs.

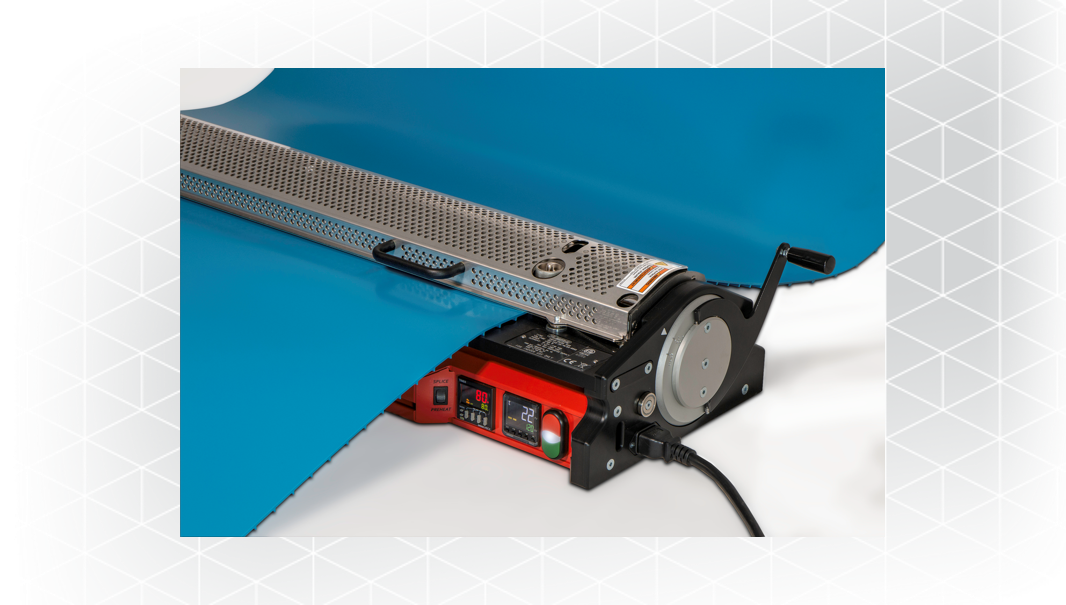

Novitool® Aero® Splice Press for Thermoplastic Belting

The Novitool® Aero® Splice Press from Flexco is everything you need to effectively combat downtime in your food processing facility. With the Aero press, you can save time and money by easily bringing your belt splicing in-house.

• Splice your belt quickly with cycle times as little as 8 minutes

• Have better control over sanitation in your facility - a built-in air-cooling system eliminates waterborne safety and hygiene issues presented with traditional water-cooled presses

• Enjoy consistent, quality splices with a 150mm effective heat zone across the entire tool width that eliminates unfilled fingers

• Avoid cross contamination by keeping your press on site, free of outside contaminants

• Never forget a splice recipe again — you can program recipes directly into the press and share recipes from press to press or site to site

Search Available Product Options

Novitool® Amigo™ Splice Press for Monolithic Belting

The Novitool® Amigo™ Splice Press creates a smooth, endless splice that is less likely to stick to conveyed food products. Everything about the Amigo press has been designed to splice your belt with ease, safety, and speed.

• Splice your belt in less than one minute

• Use the pre-heat function to remove moisture from the belt, discouraging pinholes that could house bacteria

• Safely cut the belt using the integrated belt cutter to maintain accurate pitch in a single pass

• Avoid cross contamination by keeping your press on site, free of outside contaminants

• Ensure splice parameter consistency regardless of ambient temperature with the shielded heat zone and temperature control

Search Available Product Options

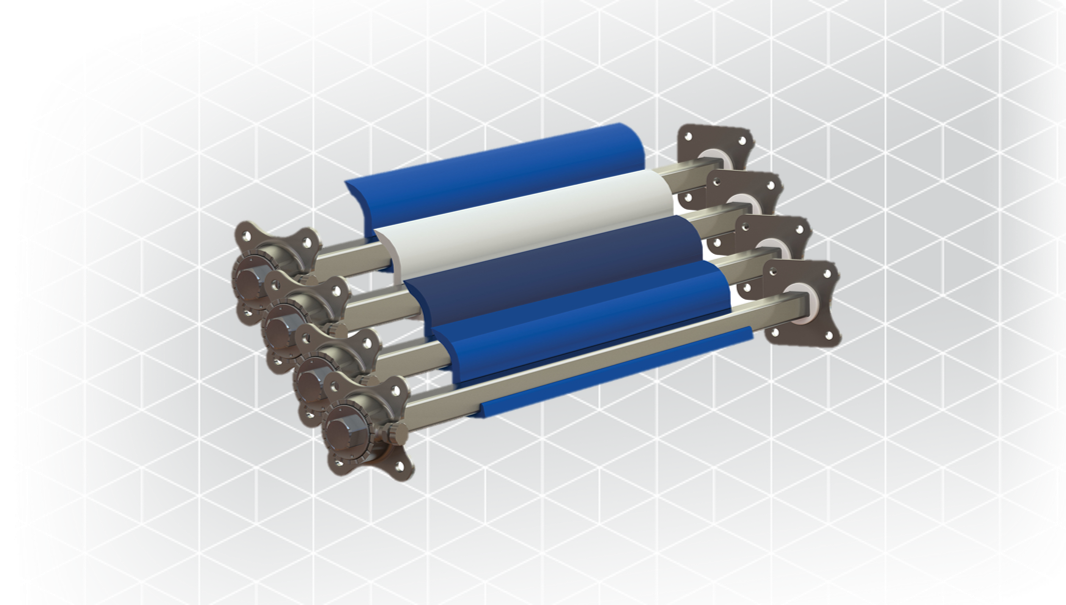

Flexco FGP Food Grade Precleaner

The FGP Food Grade Precleaner meets the highest standards for food processing. It is easy to install, easy to maintain, and disassembles in a snap for regular cleaning and sanitization. Its stainless steel components and food grade materials limit crevices and opportunities for bacteria growth.

• Eliminate carryback to protect your conveyor components from mistracking and abrasion and reduce scrap losses

• Minimize maintenance and sanitation costs

• Adjust the tensioning with ease, ensuring optimal blade-to-belt contact

• Choose your cleaner blade: White, blue, metal detectable blue, and dual durometer blue

• Rest easy, knowing that the FGP Food Grade Precleaner is FDA Approved, USDA Certified, Health Canada Approved, and EU 1935/2004 Compliant

Search Available Product Options

DISCLAIMER: The above content is provided by the supplier. Applied does not guarantee the accuracy or timeliness of the content.

The above content is provided “AS IS”, AND ANY AND ALL EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS ARE HEREBY EXCLUDED.

All warranties, if any, are solely from the supplier.

Find a Service Center

Find a Service Center