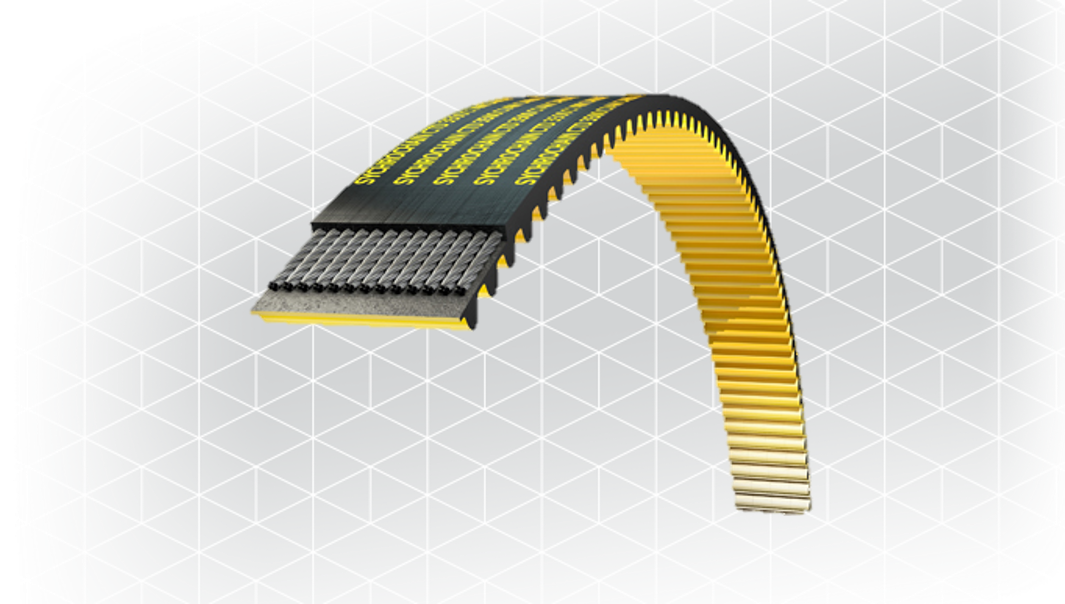

MORE REASONS WHY YOU SHOULD SWITCH TO CONTI® SYNCHROCHAIN CARBON:

SYNCHROCHAIN CARBON ADVANTAGES

- Reduces drive width by up to 5 times

- No lubrication needed - Operates clean and dry

- Smooth engagement of teeth and reduced vibration

- Quiet in operation

- High-speed capability

- 2-3x life expectancy

- Length is stable through life

CHAIN DRIVE DISADVANTAGES

- – 90% of chain drives are improperly lubricated

- – Lubrication attracts debris causing wear problems

- – Jerky motion causes vibration

- – Metal-to-metal contact makes chain drives noisy

- – Limited speed range

- – Limited life

- – Wear and elongation

WHERE CONTI® SYNCHROCHAIN CARBON CAN REDUCE COSTS:

- Conveyor Systems

- Bucket Elevators

- Overhead Hoists

- Food Processing

- Warehouses

- Foundries

- Sand & Gravel Plants

- Packaging Machines

- Pumping Stations

- Extrusion Presses

- Spindle Drives

- Feed Drives

- Wire Drawing

- Saw Mills

- Injection Molding Machines

Benefits & Features

Can be an ideal replacement for problem v-belt drives, and can also replace standard rubber timing belt drives, but in a much narrower drive envelope. Provides the end user with smooth, energy efficiency, high capacity and dramatically improved up-time.

Features

- Nearly maintenance free

- Higher power capacity

- Longer service life

- Wear-resistant

- Abrasion-resistant

Find a Service Center

Find a Service Center