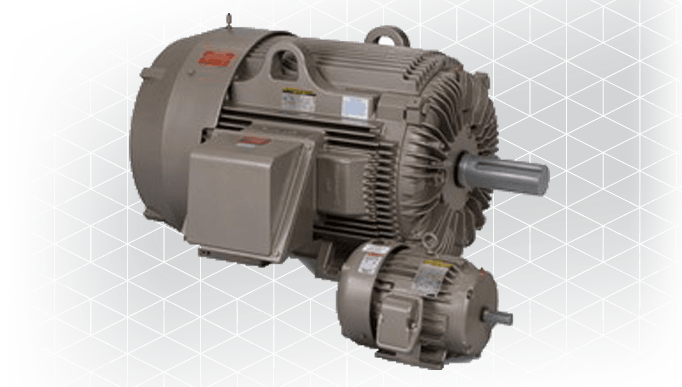

Improved Reliability, Performance, & Energy Efficiency: Baldor-Reliance Crusher Duty Motors

You need a reliable solution that can meet the demands of the toughest crushing applications. The Applied® selection of Baldor-Reliance Crusher Duty Motors does just that. With a high torque performance that exceeds the NEMA Design C locked rotor, pull up and breakdown torques, the Crusher Duty Motors are designed to help lower total cost of ownership when moving heavy-duty, long-distance loads.

Baldor-Reliance Crusher Duty Motors are Great for the Aggregate Industry:

Building on the proven reliability of our Severe Duty motors, Crusher Duty motors are designed to meet demanding aggregate industry challenges. Equipped with industry leading locked rotor and breakdown torques and above average Service Factor up to 1.25; the Crusher Duty motors are capable of reliable operation during peak loading conditions. All designs reduce total cost of ownership and increase flexible operation with NEMA Premium Efficient designs that can operate across the line or with inverter power.

A rugged all cast iron construction is enhanced with an IP55 enclosure to protect the motor in harsh environments typical for outdoor industrial applications. To ensure long life in either couple or belted applications, crusher duty motors utilize oversized ball and roller bearings. To minimize electrical damage from vibration, motors have sturdy stator coil head lacing and lead separators to prevent movement and ground faults.

• The 586/587 frame models come standard as F3 mount with capabilities to convert to F1 or F2 using a swing arm style conduit box.

• All 586/587 frame sizes have an oversized 4.375" diameter shaft with 4140 material as well as an oversized NU324 roller bearing for belted applications.

• Baldor-Reliance has also included an oversized 6322 insulated bearing on the non-drive end which is axially locked and is suitable for vertical applications.

• These motors will be provided with a terminal board for easy and convenient connection.